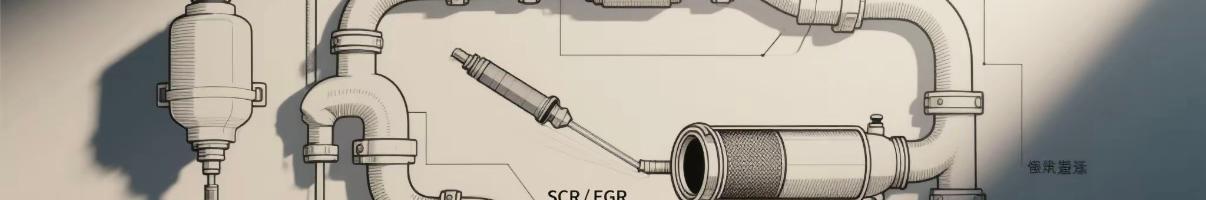

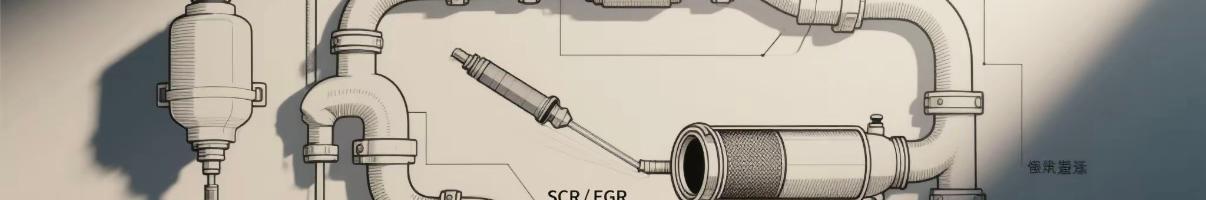

As global environmental concerns intensify, nitrogen oxide emissions (NOx) remain a major air pollutant, drawing stringent regulatory scrutiny. Diesel generators, prized for their high power density and reliability, are widely used in emergency power systems across data centers, hospitals, construction sites, and remote areas. However, their combustion process generates significant NOx, posing risks to the environment and human health, prompting the industry to adopt advanced reduction technologies. In 2025, technologies like selective catalytic reduction (SCR) systems, exhaust gas recirculation (EGR) technology, combustion optimization technology, alternative fuels, diesel oxidation catalysts (DOC), diesel particulate filters (DPF), intelligent control systems, and renewable fuels offer multidimensional solutions for NOx reduction in diesel generators. These innovations not only ensure compliance with global emission standards, such as the EU’s Stage V and U.S. EPA Tier 4, but also reduce compliance costs and environmental impact. For instance, in a Southeast Asian data center, a diesel generator equipped with an SCR system slashed NOx emissions by 85%, meeting stringent emission standards while optimizing fuel efficiency through an intelligent control system. Selective catalytic reduction (SCR) systems are among the most mature NOx reduction technologies. By injecting urea (AdBlue) into the exhaust stream, SCR converts NOx into harmless nitrogen and water vapor under a catalyst. In a North American mining operation, an SCR system reduced diesel generator NOx emissions to a quarter of EPA Tier 4 limits, improving air quality. However, SCR systems require steady urea supply and maintenance, increasing operational complexity. Intelligent control systems optimize SCR system performance by monitoring exhaust temperature, urea injection, and catalyst efficiency in real time. In a Middle Eastern oil and gas project, an intelligent control system cut SCR system operating costs by 15% by dynamically adjusting urea injection, ensuring NOx compliance. Exhaust gas recirculation (EGR) technology is another vital NOx reduction method, recirculating cooled exhaust into the combustion chamber to lower combustion temperatures and NOx formation. In an Australian construction site, an EGR technology-equipped diesel generator reduced NOx by 40%, while combustion optimization technology boosted fuel efficiency, cutting per-kWh carbon emissions by 12%.

Combustion optimization technology reduces nitrogen oxide emissions by refining fuel injection, air-fuel ratios, and combustion chamber design. 2025 diesel generators employ high-pressure common-rail injection and turbocharging for precise fuel delivery and combustion efficiency. In a South American agricultural project, combustion optimization technology cut NOx emissions by 30% while improving fuel efficiency, lowering costs. Intelligent control systems enhance combustion optimization technology by analyzing sensor data to adjust combustion parameters, ensuring low emissions across loads. In a Nordic hospital emergency power system, an intelligent control system optimized low-load modes, reducing NOx by 25% and extending maintenance intervals. While diesel oxidation catalysts (DOC) and diesel particulate filters (DPF) primarily target CO, HC, and PM, they indirectly reduce NOx by improving combustion efficiency. In an Asian data center, DOC and DPF integration cut diesel generator PM to a fifth of Stage V limits, with cleaner combustion lowering NOx. Alternative fuels and renewable fuels offer new avenues for NOx reduction. Biodiesel, a renewable fuel, reduces carbon footprint and NOx through higher oxygen content and better combustion. In a South African microgrid, a B20-powered diesel generator cut NOx by 15%, with SCR systems and EGR technology further optimizing emissions. Hydrotreated vegetable oil (HVO), another renewable fuel, with low sulfur and aromatics, significantly cuts NOx and PM. In a German standby power system, an HVO-powered diesel generator reduced NOx by 20% and CO2 by 90%, showcasing renewable fuel potential. Emerging alternative fuels like e-fuels and green hydrogen promise near-zero emissions. In a Japanese pilot, a diesel generator modified for hydrogen-blended fuel achieved near-zero NOx, marking a breakthrough.

Intelligent control systems and remote monitoring technology inject smart capabilities into NOx reduction. Intelligent control systems analyze load, temperature, and emission data to optimize SCR systems, EGR technology, and combustion optimization technology. In a Middle Eastern construction site, an intelligent control system adjusted EGR recirculation ratios, cutting NOx by 18%, while predictive maintenance preempted SCR system catalyst degradation, avoiding downtime. Remote monitoring technology enables cross-regional management, transmitting data to cloud platforms for remote diagnostics. In an African microgrid, diesel generators used satellite-linked remote monitoring technology for 24/7 emission oversight, ensuring NOx compliance in limited-network areas. In a South Asian data center, remote monitoring technology optimized diesel generator schedules, reducing NOx by 20% and maintenance costs by 15%. NOx reduction also hinges on global policies and collaboration. The EU’s European Green Deal and China’s carbon neutrality goals drive diesel generator innovation. Emission standards have tightened, spurring advancements like 30% more efficient SCR system catalysts and enhanced EGR technology thermal management. In a North American oil and gas project, a diesel generator with upgraded SCR systems and EGR technology cut NOx to a third of EPA Tier 4 limits. Policy support for renewable fuels accelerates adoption. India’s subsidies for B20 fuel reduced NOx and CO2 in diesel generators, while a South American agricultural project using HVO earned carbon credits, offsetting compliance costs.

Looking ahead, NOx reduction in diesel generators will advance through technology, fuels, and smart management. Artificial intelligence (AI) and edge computing will enhance intelligent control system precision. AI algorithms can predict optimal SCR system and EGR technology parameters, maximizing NOx reduction. In a European standby power system, an AI-driven intelligent control system cut NOx by 22% while improving fuel efficiency. Green hydrogen and e-fuels will offer near-zero-emission fuels, with commercial hydrogen-powered diesel generators expected by 2030. A German pilot using green hydrogen achieved zero NOx, setting a benchmark. Combustion optimization technology will leverage digital twins to simulate engine states, preempting issues and extending lifespans. Global collaboration will drive selective catalytic reduction (SCR) systems, exhaust gas recirculation (EGR) technology, alternative fuels, and intelligent control systems, positioning diesel generators as sustainable contributors to green energy transition and carbon neutrality. These integrated technologies not only reduce nitrogen oxide emissions but also ensure diesel generators remain vital in a low-emission future.