Views: 6 Author: Site Editor Publish Time: 2025-04-25 Origin: Site

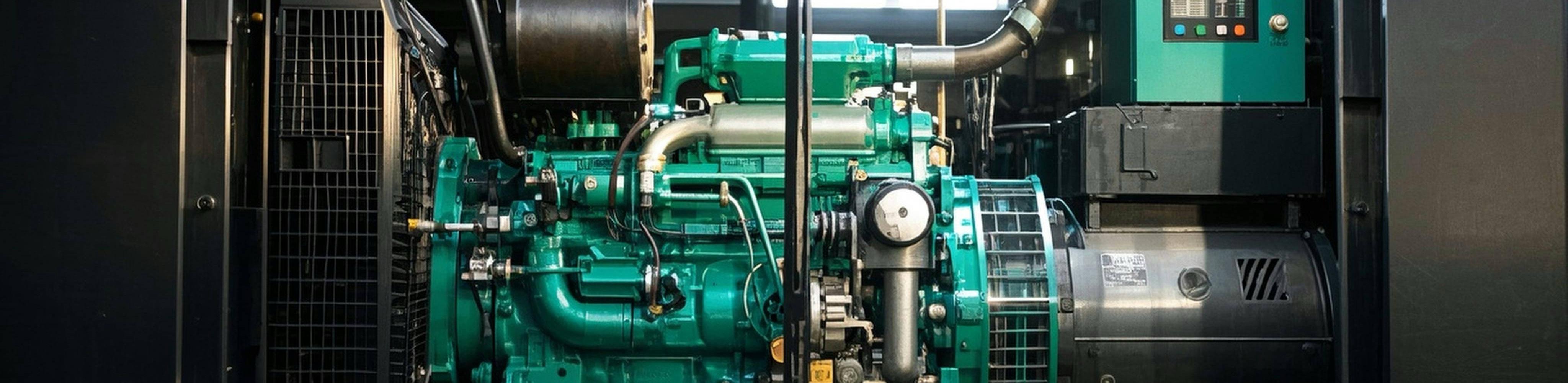

In industrial applications, a diesel generator must deliver continuous, stable power under harsh conditions. Achieving optimal performance begins with structural design—ensuring the generator can handle thermal stress, variable loads, and fuel efficiency over long operational periods.

Engine-generator matching is critical. The diesel engine’s torque and RPM must align with the alternator’s power curve to prevent overloads and unstable outputs. Copper-wound, brushless alternators are often used in high-demand scenarios to improve heat resistance and maintain steady current flow.

The cooling system is a key reliability factor. Industrial generators often operate in extreme temperatures, dusty environments, or high humidity. Effective cooling designs—such as closed-loop water cooling combined with air/oil systems—are essential to prevent overheating. Anti-rust and anti-scaling treatments in cooling channels further extend lifespan.

Fuel delivery must also be precisely controlled. A robust fuel supply system includes multi-level filtration and air separation to maintain spray accuracy and minimize injector wear. Electronic fuel injection systems can further boost fuel efficiency, reduce black smoke emissions, and improve environmental compliance.

Digital transformation in manufacturing has accelerated demand for smarter generator systems. The control panel now plays a central role in performance. Modern controllers enable automatic start/stop, diagnostics, parallel operation, remote access, and smart load management.

For parallel operation, components like the automatic voltage regulator (AVR) and frequency control module must ensure quick response and steady output. Precision in voltage and frequency control minimizes harmonic distortion and allows seamless synchronization between multiple units.

Noise reduction design is also crucial. Advanced soundproofing using acoustic insulation, silencers, and enclosures enables generators to operate in hospitals, urban zones, or data centers without causing acoustic disruption.

High-end models are now equipped with remote monitoring systems, enabling 24/7 tracking via IoT platforms. These systems support fault detection, predictive maintenance, and real-time performance metrics—enhancing uptime while reducing maintenance costs.

Industrial generators must operate in a wide range of global environments—from oil fields and mines to ports, telecom facilities, and construction sites. Their environmental adaptability is essential.

In high-altitude areas, air density drops, affecting combustion. This requires recalibrated air intake systems, turbo settings, and injection parameters. In coastal or corrosive settings, anti-rust coatings, stainless steel panels, and IP55-rated enclosures are vital for durability.

Modular design plays a role in deployment and maintenance. Integrated fuel tanks, skids, and lifting points allow for quick installation—critical in emergency or remote scenarios. Space-limited environments may demand custom low-noise, fireproof, explosion-proof, or shock-resistant enclosures.

With the global push toward carbon neutrality, manufacturers now incorporate biodiesel, hybrid systems, and energy storage with solar integration into their designs. These eco-friendly options support smarter, more flexible power management aligned with sustainable development goals.