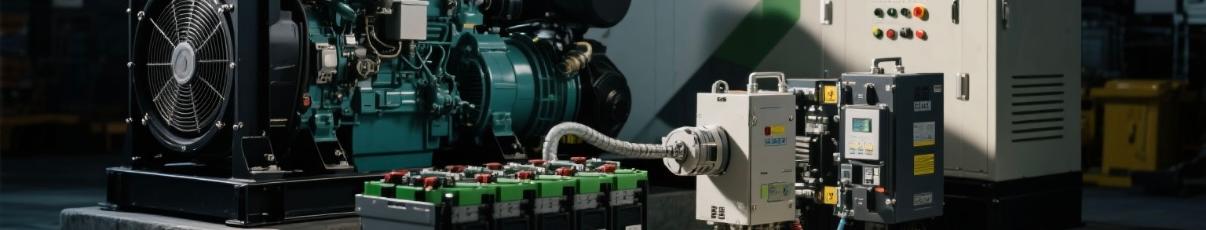

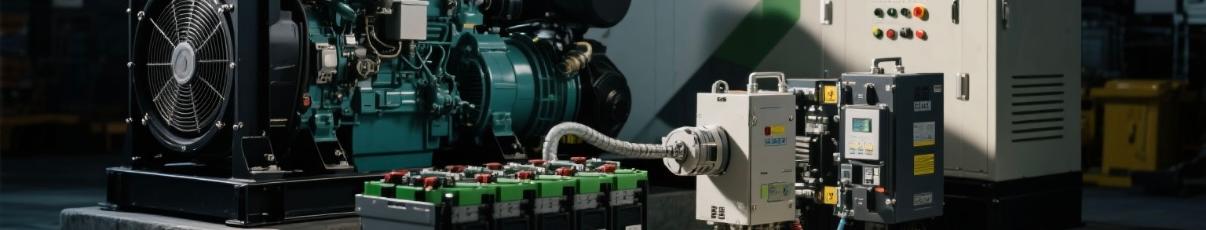

The global push for carbon neutrality is transforming the diesel generator industry toward low-carbon innovation. In 2024, the global diesel generator market was valued at ~$23 billion, projected to grow at a 5.8% CAGR to $32 billion by 2030. The International Energy Agency (IEA) forecasts net-zero power systems by 2050, with low-carbon solutions, biofuel compatibility, dual-fuel systems, exhaust gas treatment, hybrid integration, smart control systems, battery bank coupling, and energy-as-a-service reshaping the future of diesel generators. This article analyzes market trends, case studies, technological breakthroughs, and business models under low-carbon drivers, exploring how diesel generators achieve sustainability in a carbon neutrality era.

The carbon neutrality goal accelerates the adoption of low-carbon solutions. A Queensland, Australia, remote mine relied on four Caterpillar C175-20 diesel generators (8000 kW total) for off-grid power. In 2024, Australia’s 2050 Net-Zero Plan mandated 50% CO2 reduction, prompting a dual-fuel system with biofuel compatibility using B20 biodiesel, cutting carbon emissions by 20%. Exhaust gas treatment (SCR+DPF) reduced NOx by 90% and PM by 95%, meeting NPI standards. Hybrid integration via 400 kW solar PV and 1 MWh lithium battery bank coupling cut fuel use by 30% (~6000 liters/year). Smart control systems via IoT optimized load distribution, boosting operational efficiency by 15%. Energy-as-a-service via pay-per-use contracts reduced operational cost by 25% and offset 5% of emissions via carbon credits. This balanced carbon neutrality with economic viability through low-carbon solutions.

Telecom demands reliability and low emissions, with low-carbon solutions offering green alternatives. A Gujarat, India, 5G base station used two Perkins 1106D-E70TAG diesel generators (300 kW total) for backup power. In 2024, India’s NCAP required 90% PM reduction, prompting a dual-fuel system with biofuel compatibility using B30 biodiesel, cutting carbon emissions by 30%. Exhaust gas treatment (SCR+DPF) reduced NOx by 80%. Hybrid integration via 100 kW solar PV and 200 kWh battery bank coupling cut fuel use by 25% (~2000 liters/year). Smart control systems via 4G monitored load and emissions, boosting operational efficiency by 10%. Energy-as-a-service via pay-per-use reduced total cost of ownership by 20%, with National Solar Mission subsidies (40%) easing initial investment. Carbon credits offset 10% of emissions, meeting carbon neutrality goals. This leveraged low-carbon solutions and smart control systems for telecom sustainability.

Data centers require continuous power and low emissions, with low-carbon solutions enabling sustainability. A Singapore data center used four Cummins QSK23 diesel generators (8000 kW total) for backup. In 2024, Singapore’s Green Plan 2030 mandated 40% CO2 reduction, prompting a dual-fuel system with biofuel compatibility using B20 biodiesel, cutting carbon emissions by 20%. Exhaust gas treatment (SCR+DPF) reduced NOx by 90%. Hybrid integration via 400 kW solar PV and 1 MWh battery bank coupling cut fuel use by 30% (~8000 liters/year). Smart control systems via AI optimized load distribution, boosting operational efficiency by 12%. Energy-as-a-service via power contracts reduced operational cost by 25%, with carbon credits offsetting 8% of emissions, meeting environmental laws. Subsidies (35%) eased initial investment. This met data center reliability and carbon neutrality needs via low-carbon solutions.

Construction sites, with temporary loads, widely adopt low-carbon solutions. A Rio de Janeiro, Brazil, site used three Volvo Penta TWD1673GE diesel generators (2400 kW total) for cranes and lighting. In 2024, Brazil’s Renewable Energy Plan mandated 30% CO2 reduction, prompting a dual-fuel system with biofuel compatibility using B20 biodiesel, cutting carbon emissions by 20%. Exhaust gas treatment (SCR+DPF) reduced NOx by 85%. Hybrid integration via 200 kW solar PV and 400 kWh battery bank coupling cut fuel use by 25% (~4000 liters/year). Smart control systems via 4G monitored load and emissions, boosting operational efficiency by 10%. Energy-as-a-service via pay-per-use contracts reduced total cost of ownership by 20%, with carbon credits offsetting 5% of emissions. Subsidies (40%) optimized initial investment. This met construction flexibility via low-carbon solutions and hybrid integration.

Oil and gas, with high energy demands, traditionally rely on diesel generators, but low-carbon solutions offer green alternatives. A Saudi Arabian offshore platform used six Cummins QSK60 diesel generators (9600 kW total). In 2024, Saudi Vision 2030 mandated 50% CO2 reduction, prompting a dual-fuel system with biofuel compatibility using B30 biodiesel, cutting carbon emissions by 30%. Exhaust gas treatment (SCR+DPF) reduced NOx by 90% and PM by 95%. Hybrid integration via 600 kW solar PV and 1.2 MWh battery bank coupling cut fuel use by 30% (~12000 liters/year). Smart control systems via satellite optimized load distribution, boosting operational efficiency by 15%. Energy-as-a-service via pay-per-use contracts reduced operational cost by 25%, with carbon credits offsetting 10% of emissions. Subsidies (50%) eased initial investment. This met oil and gas carbon neutrality needs via low-carbon solutions.

Hospitals require reliable power, with low-carbon solutions providing green options. A Dubai, UAE, hospital used three Cummins QSK23 diesel generators (3600 kW total) for ICU backup. In 2024, UAE’s 2050 Energy Strategy mandated 40% CO2 reduction, prompting a dual-fuel system with biofuel compatibility using B20 biodiesel, cutting carbon emissions by 20%. Exhaust gas treatment (SCR+DPF) reduced NOx by 90%. Hybrid integration via 300 kW solar PV and 600 kWh battery bank coupling cut fuel use by 25% (~5000 liters/year). Smart control systems via 4G monitored load and emissions, boosting operational efficiency by 12%. Energy-as-a-service via power contracts reduced total cost of ownership by 20%, with carbon credits offsetting 5% of emissions. Subsidies (40%) optimized initial investment. This met hospital reliability and carbon neutrality needs via low-carbon solutions.

Community electrification showcases low-carbon solutions. A Manila, Philippines, remote community used three Cummins QSB6.7 diesel generators (1500 kW total) for lighting and medical equipment. In 2024, the Philippines’ Renewable Energy Act mandated 30% CO2 reduction, prompting a dual-fuel system with biofuel compatibility using B20 biodiesel, cutting carbon emissions by 20%. Exhaust gas treatment (SCR+DPF) reduced NOx by 85%. Hybrid integration via 300 kW solar PV and 500 kWh battery bank coupling cut fuel use by 25% (~4000 liters/year). Smart control systems via IoT monitored load and emissions, boosting operational efficiency by 12%. Energy-as-a-service via pay-per-use contracts reduced total cost of ownership by 20%, with carbon credits offsetting 5% of emissions. Subsidies (40%) optimized initial investment. This met community carbon neutrality needs via low-carbon solutions.

Policy support drives low-carbon adoption. A Jiangsu, China, industrial park, with 40% subsidies from the Green Manufacturing Initiative, deployed three Cummins QSK23 diesel generators (6000 kW total) with 400 kW solar PV and 1 MWh battery bank coupling in a hybrid integration system. A dual-fuel system with biofuel compatibility using B20 biodiesel cut carbon emissions by 20%. Exhaust gas treatment (SCR+DPF) reduced NOx by 90%. Battery bank coupling cut fuel use by 30% (~7000 liters/year). Smart control systems via AI optimized load distribution, boosting operational efficiency by 15%. Energy-as-a-service via pay-per-use contracts reduced operational cost by 25%, with carbon credits offsetting 10% of emissions. This accelerated carbon neutrality via low-carbon solutions.

By 2035, low-carbon solutions will dominate 50% of the diesel generator market. Biofuel compatibility via HVO will cut carbon emissions by 50%. Dual-fuel systems with hydrogen will reduce fossil fuel use by 80%. Exhaust gas treatment costs will drop 30% via new materials. Hybrid integration with solid-state battery bank coupling will boost energy density by 50% and cut fuel use by 40%. Smart control systems via 6G and AI will improve operational efficiency by 20%. Energy-as-a-service will capture 50% of the market, offsetting 30% of emissions via carbon credits. Cummins plans hydrogen-fueled diesel generators by 2027, and Caterpillar is developing low-emission smart control systems. Manufacturers must leverage subsidies to optimize initial investment and operational cost for carbon neutrality.

In conclusion, low-carbon solutions via biofuel compatibility, dual-fuel systems, exhaust gas treatment, hybrid integration, smart control systems, battery bank coupling, and energy-as-a-service drive the diesel generator industry toward carbon neutrality. Policy support and market demand ensure a sustainable future.